News

Consistency in Processing

If processing hot dogs is so easy, why is that so often it just doesn’t work out right? Have you ever made a batch and thought, “WOW, this is a great batch of hot dogs.” Shouldn’t every batch be that way? Making wieners is basic sausage manufacturing, however consistent results requires the discipline to follow strict processing steps batch after batch.

Every processor will have his or her own recipe, including the meat block and seasoning formulation. Recipes are typically adjusted and tweaked to appeal to the largest mass of a processor’s customer base. The key to the success of any recipe is consistency in replication. Batch after batch the product must meet the expected end result. A good procedure should be written down, communicated to employees, and followed rigorously every single load. Good manufacturing processes and quality control procedures are really nothing more than a HACCP plan for product quality.

The goal of this article is to identify variables in processing that can lead to inconsistent loads, provide solutions to common errors, and to provide guidelines to ensure those errors do not occur in the future. As with any processing procedure, it is important to evaluate the individual steps and stages in order to tighten up the process and optimize for best possible consistency and quality. Let’s start with the grinding and mixing process.

STEP 1: GRINDING & MIXING

The goal in grinding and mixing is to make a batter that has a good protein matrix that binds the fat and water molecules as well as produces the desired mouth-feel and bite. Regardless of your meat block, protein additives, or equipment, the variables that will determine your “bind” are time in mechanical manipulation, and temperature. Proteins in the meat are salt soluble, so make sure to add the salt early in the process and give it time in the mixer (or bowl chopper) to pull proteins out. Pulling proteins requires time in the mixer, however too much time will break down the matrix. Pay close attention to temperature as break down occurs when temps are allowed to exceed 55 degrees F. The questions for this step of the process are, 1) How am I controlling (or monitoring) the time to ensure I extrude protein and get the best possible mix? And 2) How am I controlling the temperature of the mix to ensure I don’t exceed 55F and start breaking down the matrix

The goal in grinding and mixing is to make a batter that has a good protein matrix that binds the fat and water molecules as well as produces the desired mouth-feel and bite. Regardless of your meat block, protein additives, or equipment, the variables that will determine your “bind” are time in mechanical manipulation, and temperature. Proteins in the meat are salt soluble, so make sure to add the salt early in the process and give it time in the mixer (or bowl chopper) to pull proteins out. Pulling proteins requires time in the mixer, however too much time will break down the matrix. Pay close attention to temperature as break down occurs when temps are allowed to exceed 55 degrees F. The questions for this step of the process are, 1) How am I controlling (or monitoring) the time to ensure I extrude protein and get the best possible mix? And 2) How am I controlling the temperature of the mix to ensure I don’t exceed 55F and start breaking down the matrix

STEP 2: Keep the Product Moving

This step is relatively straightforward. The skill and craftsmanship of those performing the task will lend the largest variable. The one variable in this step of the process that links it to the smoking operation (no pun intended) is the time it takes to load the smoke truck or smokehouse. Often times loading errors are due to interruptions or simply the amount of time it takes to load the smokehouse. When these errors occur, the product is introduced to the smokehouse in varying degrees of readiness. The first product hung may have a dry surface and be a few degrees ahead of the last product, which will more than likely have a wet surface. This brings us to the smoking stage.

This step is relatively straightforward. The skill and craftsmanship of those performing the task will lend the largest variable. The one variable in this step of the process that links it to the smoking operation (no pun intended) is the time it takes to load the smoke truck or smokehouse. Often times loading errors are due to interruptions or simply the amount of time it takes to load the smokehouse. When these errors occur, the product is introduced to the smokehouse in varying degrees of readiness. The first product hung may have a dry surface and be a few degrees ahead of the last product, which will more than likely have a wet surface. This brings us to the smoking stage.

STEP 3: SMOKING & CONDITIONING

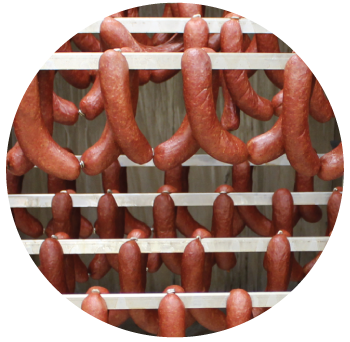

One of the most overlooked stages in setting up a smoke or cook cycle is the conditioning stage. This stage is to simply level out the product to get the entire batch to the same level of surface moisture as well as internal temperature. Some processors accomplish this by hosing down the newly loaded smokehouse truck with cold water and let it sit for 10 to 20 minutes prior to rolling the truck into the smokehouse. In a gravity fed smokehouse it may mean that the product is hung in a cooler for a determined amount of time, then the house is loaded quickly and the process started. In a controlled atmosphere house, it might be that a shower cycle starts off the program, or a cycle of low-heat high-humidity levels out the condition of product in the truck smoker. The key is if we want the product to be consistent throughout the smokehouse, the product must be in the same condition throughout the smokehouse. The total program is going to be determined by your equipment, the amount of smoke flavor, and the color you are looking to achieve. With natural smoke, settings should be set to: dry to tacky – smoke - short set cycle – cook. Natural smoke imparts a darker color at higher humidity (65%-85%). Ramping temperature up in steps will result in a better yield. Smokehouse temperature is a major contributing factor in product color and by ramping temperature up in multiple steps, you will obtain a better result in yield and product quality. If you change only one parameter per load to see the result, you will better understand your smokehouse in the long run!

One of the most overlooked stages in setting up a smoke or cook cycle is the conditioning stage. This stage is to simply level out the product to get the entire batch to the same level of surface moisture as well as internal temperature. Some processors accomplish this by hosing down the newly loaded smokehouse truck with cold water and let it sit for 10 to 20 minutes prior to rolling the truck into the smokehouse. In a gravity fed smokehouse it may mean that the product is hung in a cooler for a determined amount of time, then the house is loaded quickly and the process started. In a controlled atmosphere house, it might be that a shower cycle starts off the program, or a cycle of low-heat high-humidity levels out the condition of product in the truck smoker. The key is if we want the product to be consistent throughout the smokehouse, the product must be in the same condition throughout the smokehouse. The total program is going to be determined by your equipment, the amount of smoke flavor, and the color you are looking to achieve. With natural smoke, settings should be set to: dry to tacky – smoke - short set cycle – cook. Natural smoke imparts a darker color at higher humidity (65%-85%). Ramping temperature up in steps will result in a better yield. Smokehouse temperature is a major contributing factor in product color and by ramping temperature up in multiple steps, you will obtain a better result in yield and product quality. If you change only one parameter per load to see the result, you will better understand your smokehouse in the long run!

Take a good look at your process and evaluating the steps to control variables so that each and every time you open the smokehouse door you can say, “WOW, what a great batch of hot dogs.”

PS Seasoning & Spices, Pro Smoker and Vortron Smokehouses would like to point out that this concept can and should be utilized with all your products for uniformity and consistency.

Our Team of Experts Will Assist You With Your Plan:

Pro Smoker and Vortron Smokehouses: smokehouses and pellet generators designed for product uniformity and consistency by utilizing Clean-Smoking™ technology. Achieve that deep smoke flavor, rich surface color and temperature uniformity with our proven smokehouses designed for even air exchange.

- pro-smoker.com, vortronsmokehouses.com

PS Seasoning & Spices: leading in flavor innovation, PS seasoning & Spices serves the food and beverage industry offering product development, custom blends, co-packing, and private label. SQF Level 2.

- blendwithps.com

Consistency in Processing

Pro Flavor

Featured Smoker Recipes

Smoked Venison Chili